Hollow O-Rings – Hollow Core – Hollow Cord:

Hollow O-rings work the same as regular O-rings. The difference between a regular O-ring and a Hollow ring is the fact that the hollow core makes it much easier to compress the ring. In the event that enclosure tolerances are large or the available compressive force is low, Simolex engineers can design a custom hollow seal to help absorb large tolerances while providing very low compressive force compared to solid cord. Hollow O-rings are an economical alternative to standard O-rings, when low closing force is required. The reduced closing force is achieved by replacing the solid cross-section by a hollow cross-section, without reducing the material hardness. Hollow O-rings are used for instance for sealing lids and doors

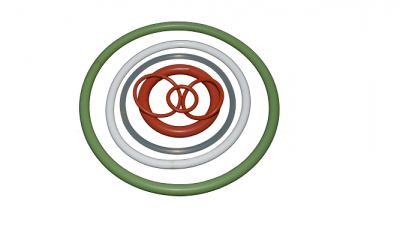

Extruded & Spliced -Vulcanized O Rings:

Simolex Rubber Corporation manufacture Solid or hollow O rings. Simolex utilizes a hot vulcanizing bonding process to splice our Solid or Hollow O-Rings. They are fabricated with a unique vulcanizing technique which makes the joints as smooth as molded parts. We can also join hollow cross sections in a way that the joint has the same compressibility as the length of the gasket. Our Splicing Compound is the same base polymer as the extrusion, giving it equal properties of the seal. We manufacture large variety of Extruded and Spliced, vulcanized silicone O-rings, from silicone cord, silicone tubing, silicone square/rectangular, and from custom extruded gaskets, Seal and variety of different rubber compound that are approved by UL, ASTM D2000, NSF STD-51, USP CL-VI and FDA 21 CFR177.2600. Available hardness from 20 up to 75 shore A.

Shorter Delivery Time:

A short, less than two-weeks delivery time provides accelerated design validation prior to production launch. When customers require confirmation that the Hollow O Ring will properly fit the application and provide the needed compression force, the Rapid Prototype Program can reduce the overall lead time.

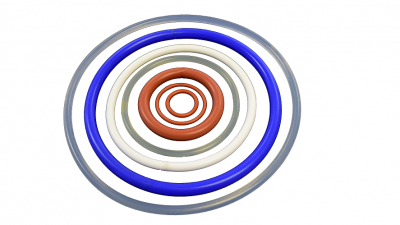

Hollow O Rings are suitable for:

- Applications where low closing force is required.

- Applications with rough surface finish.

- Automotive Applications.

- Electronic Equipment Transit Cases.

- Handheld Electronics & Communication Devices.

- Low pressure static and enclosure sealing requirement.

- Outdoor Electronics & Communications Enclosure.

- Power Generation Plants.

- Semiconductor Applications.

Hollow O Rings are not suitable for:

- Dynamic applications.

- High pressure applications.

Advantage of Simolex’s Extruded & Spliced Products:

- Can be used in standard or non-standard grooves.

- Ease of adjusting closure force by adjustment of harness of material, cross-section ID, cross-section wall thickness and cross-sectional shape.

- Hollow cross sections are best replacement for foam or sponge gaskets which offer Low closure force sealing solutions.

- Low-cost option for static face, axial or radial seal O-rings.

- Low tooling cost and flexibility of the extrusion tooling.

- No tooling required for standard O.D. / I.D. combinations Hollow O-Rings.

- Products can be vulcanized from a variety of solid and hollow cross-section.

- State of the art hot vulcanization capability.

- Superior compression set resistance.

- Tight tolerance extrusion

Visit This Link to access O-ring cut length calculator.